Off-Line By-Pass Type Filter

BK04 series

Specifications

-

Type: High Pressure By Pass Type

-

Medium: Micro fiber

-

Accuracy: 3 u

-

Filtration Area: 0.316 M2

-

Inlet Pressure P: 0.7 to 32 MPa

-

Outlet Back Pressure T<0.3MPa(differential indicator only) (Hydraulic Symbol)

-

Flow: 3 l/min Maximum

-

Temperature: -20~120 °C

-

Viscosity: 1~680 cSt

-

Trigger Pressure: 0.2 MPa

-

Weight: 2 Kg

-

Oil Ports: P-1/4 BSPT

Flow ≤ 2 l/min T-1/4 BSPT

Flow>2 l/min T-3/8 BSPT

Features & Benefit

-

Standard micro-glass-fiber media for long life and excellent system protection

-

New design prevents blockade on the Inlet port.

-

Differential pressure indicator is more reliable compared with pressure gauge.

-

Oil cake effect improves filter effectiveness.

-

Huge filtration area holds more dirts as much as conventional cylindrical paper basis design.

-

Long service life and robust appearance.

-

Change the oil box simply.

Instructions & Precautions

-

Suitable for petroleum oils, water-glycols, water-oil emulsions, and HWCF

-

Connect P port to the system primary pressure line.

-

With pressure gauge as indicator, direct T port to oil tank with hose length as short as possible.

The hose should not be less than 8mm inside diameter and be limited to 2 meter in length. -

Filter with differential pressure indicator as an alarm device, T port should be directed to oil tank or

connected to the machine manifold block in which the drain pressure must be less than 0.3 MPa. -

Replace oil filter box when pressure gauge is shown at 0.2 MPa or alarm device is triggered.

-

Disposal of the oil filter box according to environmental protection.

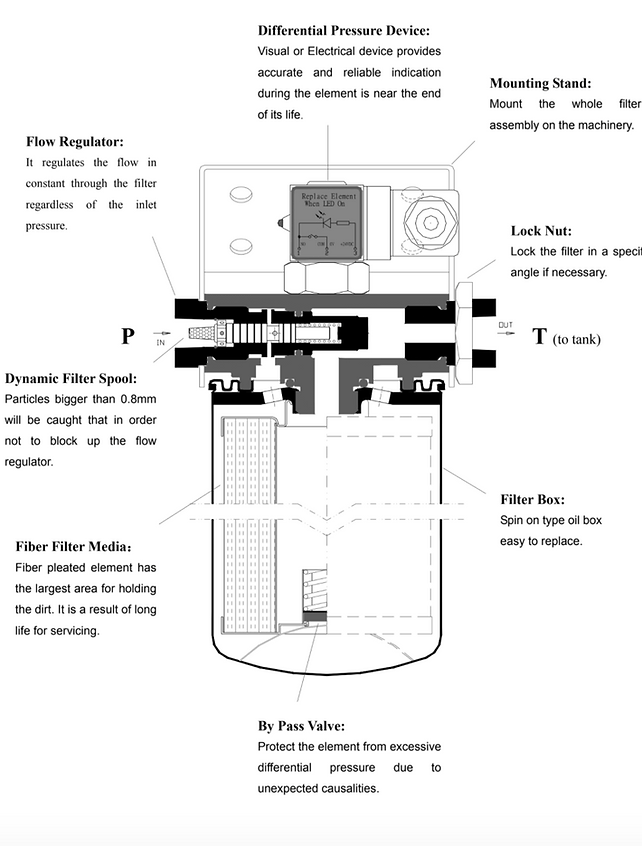

Filter Structure

Hydraulic Informations

Flow volume dissipation:

It has a flow volume loss by using of the By Pass type filter in the hydraulic system. Users must make sure that

there is enough flow for their system to work especially for very small pump flow.

Feeding of the incoming oil:

Oil to be fed to the filter is branched along the primary high pressure line located at the main pump outlet. It may

be branched at-

1. Downstream of the pump outlet

2. Main relief valve pressure detecting plug

3. Manifold block blind plug

Use a stop valve is optional for the filter as it allows for replacement of the oil box while the machine is in operation.

Return of the outgoing oil:

It is advised the returning oil directly at the oil tank in which minimum pressure exists. Alternatively, it may be

returned to-

1. Blind plug on the oil tank

2. Manifold block drain hole blind plug(not applicable

to filter with pressure gauge as indicator)

Indicator Information:

Electrical Type:

Output: Normal Open Type Contact

Contact Load: 10W / 100Vdc 0.5 A Max

Visual Indication: Red LED Emitter (Only for S4 & S5)

Voltage Supply: 24 - 36Vdc (Only for S4 & S5)

Trigger Differential Pressure: 0.18 - 0.2 Mpa

Reset Differential Pressure: 0.13Mpa

Ambient Temperature: -20°C - 120°C

Protection: Water and Mist

Connector: DIN43650 Plug

Visual Type:

Output Indication: Blue to Red

Trigger Differential Pressure: 0.18 - 0.2 Mpa

Reset Differential Pressure: Automatic Reset

Ambient Temperature: -20°C - 90°C

Protection: Water and Mist

Installation

Order Information

Filter Assembly: BK04-030-F-B-N-10-X-S* P

Oil Filter Box: SP01-030-F

-

Filtration Rating: 030 - 3um (other ratings please contacts us)

-

Filtration Medium: F - Micro glass Fiber

-

By Pass Valve: B - 0.25MPa

-

Seal Material: N - Buna ; V - Viton

-

Design Reference: 10

-

Flow Rate: X -1.5 l/min ; Y - 2 l/min ; Z -3 l/min (contact us beyond these ratings)

-

Alarm Indicator: S1 - Pressure gauge; S2 - Visual ; S3 - Electrical; S4- Electrical c/w LED(0V COM);

S5 - Electrical c/w LED(+24V COM) -

Option: P- Gauge indicated blockage of flow regulator (For differential Alarm Indicator only)